Your blog category

JEWELLERY ELEMENTS DETACHING

After the casting steps are finished the result is a precious metal jewelry tree. The jewelry tree goes to the bench jeweler who then detaches each jewelry component from the main sprue by cutting the sprue with either pliers or a saw.

- Published in Blog

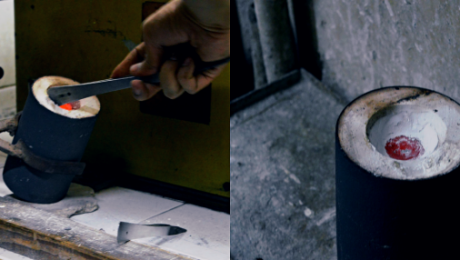

RUBBER MOLD MAKING

Mold is a the key component when creating multiple pieces of jewelry. Correctly made and cut mold is the first step in jewelry production manufacturing process.

At Unver Casting, meticulous attention is paid to each and every stage of manufacturing. Mold-making is a particularly delicate process, and Unver has it down to a science.

A Mold is a hollowed-out cavity which makes up the negative form of a final product. When filled with a certain material, cavity of the Mold produces a replica of the final product.

Many times the type of rubber that is used to cut your molds will greatly affect your finished product. That is why we offer many different types of rubber, depending on your specific needs. We will always be available to help you choose which rubber is best suited to your design.

As far as jewelry applications are concerned, Mold is used almost entirely for creating multiple duplicates, rapid prototyping, of the “Master Model” of a jewelry piece to be used later in investment casting. Mold is injected with hot wax until the cavity is completely full. The wax cools and solidifies in the shape of the cavity and therefore in the shape of the final product. Mold is then separated and a duplicate wax Model of the final product is removed out of the cavity. This process is repeated to produce multiple Models of the final product. Depending on the material used to produce it, a Mold can be used many times until the quality of the Models it produces degrades.

When creating multiple pieces, jewelry molds become an essential ingredient in the production process. Numerous wax or plastic replicas of a model can be created from a mold in order to cast multiple pieces.

Our Standard Vulcanized rubber mold is used in conjunction with metal models since the model must be able to resist both heat (greater than 300 degrees Fahrenheit) and pressure. Rubber is the material used in production and this process is most economical when the production run is relatively large.

- Published in Blog

CASTING

The desired steel alloy is melted and subsequently brought to casting temperatures. After the tree has been sintered, the tree is removed from the oven by a robotic arm and poured with metal. Once the trees have been poured, they are placed on a cooling conveyor where they are cooled with nitrogen.

Our metals are melted and poured in a highly computer controlled vacuum environment. Our latest state-of-the-art casting machines are equipped with the computer controlled programs in order to maintain exact control over the entire casting process, ensuring the highest quality porosity-free castings. Our Platinum castings are the finest. Our Gold castings selection in different karats and gold colors is of an uncompromising quality while we deliver the same results in silver, palladium, titanium, brass, bronze and stainless steel.

.

- Published in Blog

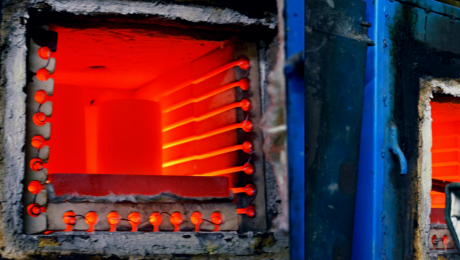

KILN

The ceramic tree is then baked (stoked) at high temperatures and reaches its final strength through the sintering process. Any wax remains are burned out during this process.

Before burning the investment is allowed to completely dry, which can take 16 to 48 hours. Drying can be enhanced by applying a vacuum or minimizing the environmental humidity. It is then turned upside-down and placed in a furnace or autoclave to melt out and/or vaporize the wax. Most shell failures occur at this point because the waxes used have a thermal expansion coefficient that is much greater than the investment material surrounding it, so as the wax is heated it expands and induces great stresses. In order to minimize these stresses the wax is heated as rapidly as possible so that the surface of the wax can melt into the surface of the investment or run out of the mold, which makes room for the rest of the wax to expand. In certain situations holes may be drilled into the mold beforehand to help reduce these stresses. Any wax that runs out of the mold is usually recovered and reused.

The mold is then subjected to a burnout, which heats the mold between 870 °C and 1095 °C to remove any moisture and residual wax, and to sinter the mold. Sometimes this heating is also used as the preheat, but other times the mold is allowed to cool so that it can be tested. If any cracks are found they can be repaired with ceramic slurry or special cements.

- Published in Blog

The ceramic mould, known as the investment, is produced by three repeating steps: coating, stuccoing, and hardening. The first step involves dipping the cluster into a slurry of fine refractory material and then letting any excess drain off, so a uniform surface is produced.

The process is to place the cluster upside-down in a flask and then liquid investment material is poured into the flask. The flask is then vibrated to allow entrapped air to escape and help the investment material fill in all of the details

The ceramic mould, known as the investment, is produced by three repeating steps: coating, stuccoing, and hardening. The first step involves dipping the cluster into a slurry of fine refractory material and then letting any excess drain off, so a uniform surface is produced.

The process is to place the cluster upside-down in a flask and then liquid investment material is poured into the flask. The flask is then vibrated to allow entrapped air to escape and help the investment material fill in all of the details

- Published in Blog

Wax Model, or sometimes called Cast or Pattern, is a replica of the final product generally produced using a preliminary material. Jewelry elements are best made with wax which has the flexibility to be built-up into almost any form you can imagine.

WAX DESIGN