Mold is a the key component when creating multiple pieces of jewelry. Correctly made and cut mold is the first step in jewelry production manufacturing process.

At Unver Casting, meticulous attention is paid to each and every stage of manufacturing. Mold-making is a particularly delicate process, and Unver has it down to a science.

A Mold is a hollowed-out cavity which makes up the negative form of a final product. When filled with a certain material, cavity of the Mold produces a replica of the final product.

Many times the type of rubber that is used to cut your molds will greatly affect your finished product. That is why we offer many different types of rubber, depending on your specific needs. We will always be available to help you choose which rubber is best suited to your design.

As far as jewelry applications are concerned, Mold is used almost entirely for creating multiple duplicates, rapid prototyping, of the “Master Model” of a jewelry piece to be used later in investment casting. Mold is injected with hot wax until the cavity is completely full. The wax cools and solidifies in the shape of the cavity and therefore in the shape of the final product. Mold is then separated and a duplicate wax Model of the final product is removed out of the cavity. This process is repeated to produce multiple Models of the final product. Depending on the material used to produce it, a Mold can be used many times until the quality of the Models it produces degrades.

When creating multiple pieces, jewelry molds become an essential ingredient in the production process. Numerous wax or plastic replicas of a model can be created from a mold in order to cast multiple pieces.

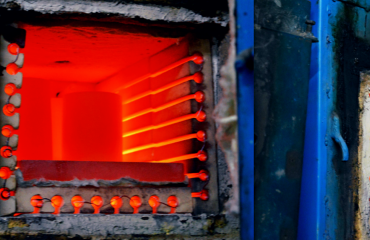

Our Standard Vulcanized rubber mold is used in conjunction with metal models since the model must be able to resist both heat (greater than 300 degrees Fahrenheit) and pressure. Rubber is the material used in production and this process is most economical when the production run is relatively large.