- Home

- Catalogues

- Makki Madni Volume 03

- Makki Madni Volume 04

- Makki Madni Volume 05

- Makki Madni Volume 06

- Makki Madni Volume 07

- Makki Madni Volume 08

- Makki Madni Volume 09

- Makki Madni Volume 10

- Makki Madni Volume 11

- Makki Madni Volume 12

- Makki Madni Volume 13

- Makki Madni Volume 14

- Makki Madni Volume 15

- Makki Madni Volume 16

- Makki Madni Volume 17

- Makki Madni Volume 18

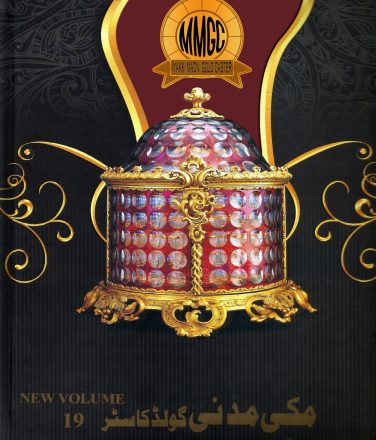

- Makki Madni Volume 19

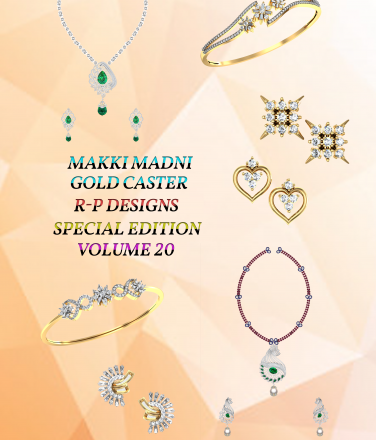

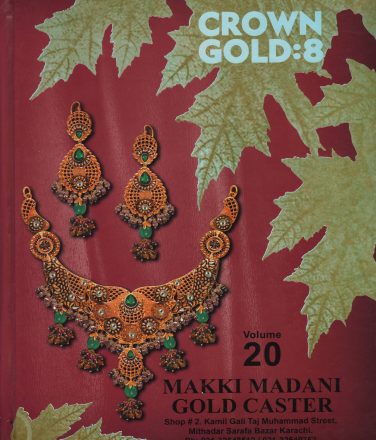

- Makki Madni Volume 20

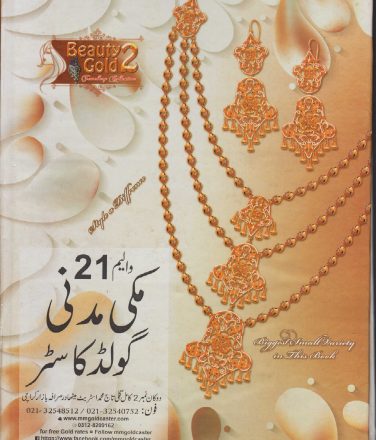

- Makki Madni Volume 21

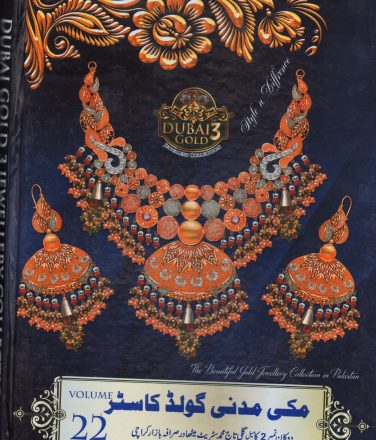

- Makki Madni Volume 22

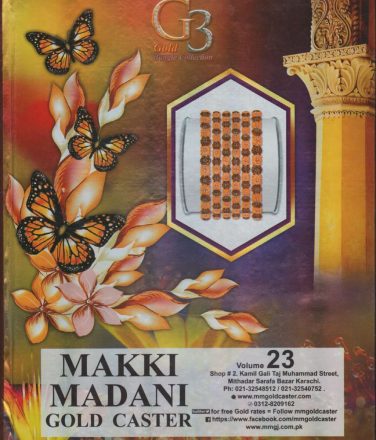

- Makki Madni Volume 23

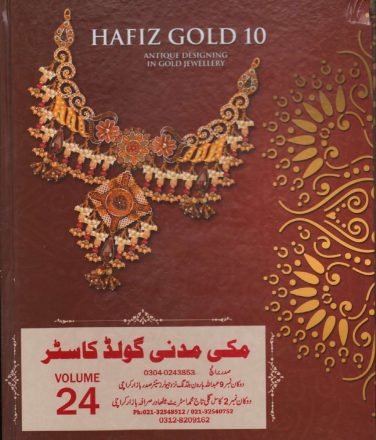

- MAKKI MADNI VOLUME 24

- Files

- Special Edition

- R – P Turkish Design VOLUME 1

- R – P Diamond Work Design VOLUME 2

- R – P Diamond Work Design VOLUME 3

- R – P Diamond Work Design VOLUME 4

- R – P PK SPECIAL EDITION VOLUME 5

- R – P SPECIAL EDITION VOLUME 6

- R – P Diamond Works Design VOLUME 7

- R – P Diamond Works Design VOLUME 8

- R – P Diamond Works Design VOLUME 9

- R – P Diamond Works Design VOLUME 10

- R – P Turkish Design

- R – P Kuwaiti Designs Volume 11

- R – P SPECIAL EDITION 12

- R – P PARA ALL SPECIAL EDITION VOLUME 13

- R – P Special Edition Volume 14

- R – P Special Edition Volume 15

- R – P Special Edition Volume 16

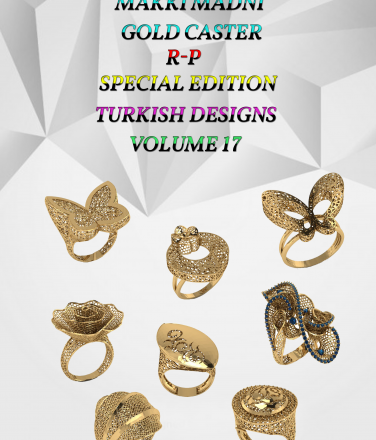

- R – P Special Edition Volume 17

- R – P Special Edition Volume 18

- R – P Special Edition Volume 19

- R – P Special Edition Volume 20

- R – P Special Edition Volume 21

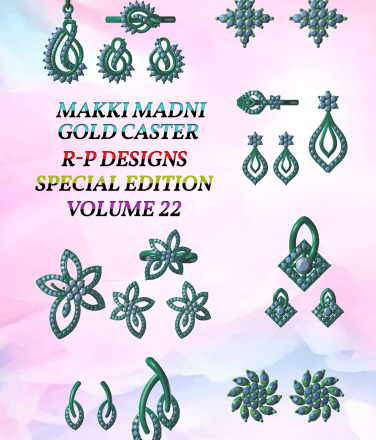

- R – P Special Edition Volume 22

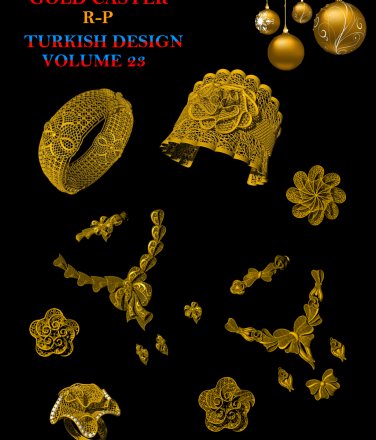

- RP – Design Turkish Volume 23

- RP Design – Volume 24 kuweti design

- R-P MOLD DESIGN Volume 25

- About us

- Contact page

Makki Madni is a Jewelry manufacturer & is a proud owner of more than 1 million of gold designs it was founded by mr. mohammad ashfaq in 1992 and we have a high technology machines and a highly experience workers to make a perfection in a design , we thought that “Quality is not an accident ; it’s a result of intelligent effort “.

0092-021-32548512

Email: [email protected]

Makki Madni Gold Caster

Sarafa Branch : Shop #2 Np4/57 Taj Muhammad St, Kamil Gali Saraffa Bazaar,Mithadar ,Karachi ,74000 Saddar branch : Dundas St, Saddar, Karachi, Karachi City, Sindh

Makki Madni3 key advantages

At Makki Madni , it's all about you. Your design specifications. Your creative vision. Your preferences. Your expectations. Your timeline.

Technology

Year after year, we’ve continued to invest in the latest equipment, recruit and train the best technicians, and stay current with the latest technology and trends.

Capacity

Our single-minded focus on customer satisfaction has earned us the business and trust of individual artists and independent jewelry retailers as well as large corporations.

Quality & Experience

Our experience and knowledge of the casting industry makes it possible for us to maintain costs with consistent high quality and meet delivery dates.

Read more +11 April 2016 By mmgoldcaster in Uncategorized

Read more +11 April 2016 By mmgoldcaster in UncategorizedJEWELLERY ELEMENTS DETACHING

After the casting steps are finished the result is a precious metal jewelry tree. The jewelry tree goes to the bench jeweler who then detaches each jewelry component from the main sprue by cutting the sprue with either pliers or a saw.

Read more +11 April 2016 By mmgoldcaster in Uncategorized

Read more +11 April 2016 By mmgoldcaster in UncategorizedRUBBER MOLD MAKING

Mold is a the key component when creating multiple pieces of jewelry. Correctly made and cut mold is the first step in jewelry production manufacturing process. At Unver Casting, meticulous attention is paid to each and every stage of manufacturing. Mold-making is a particularly delicate process, and Unver has it down to a science. A

Read more +11 April 2016 By mmgoldcaster in Uncategorized

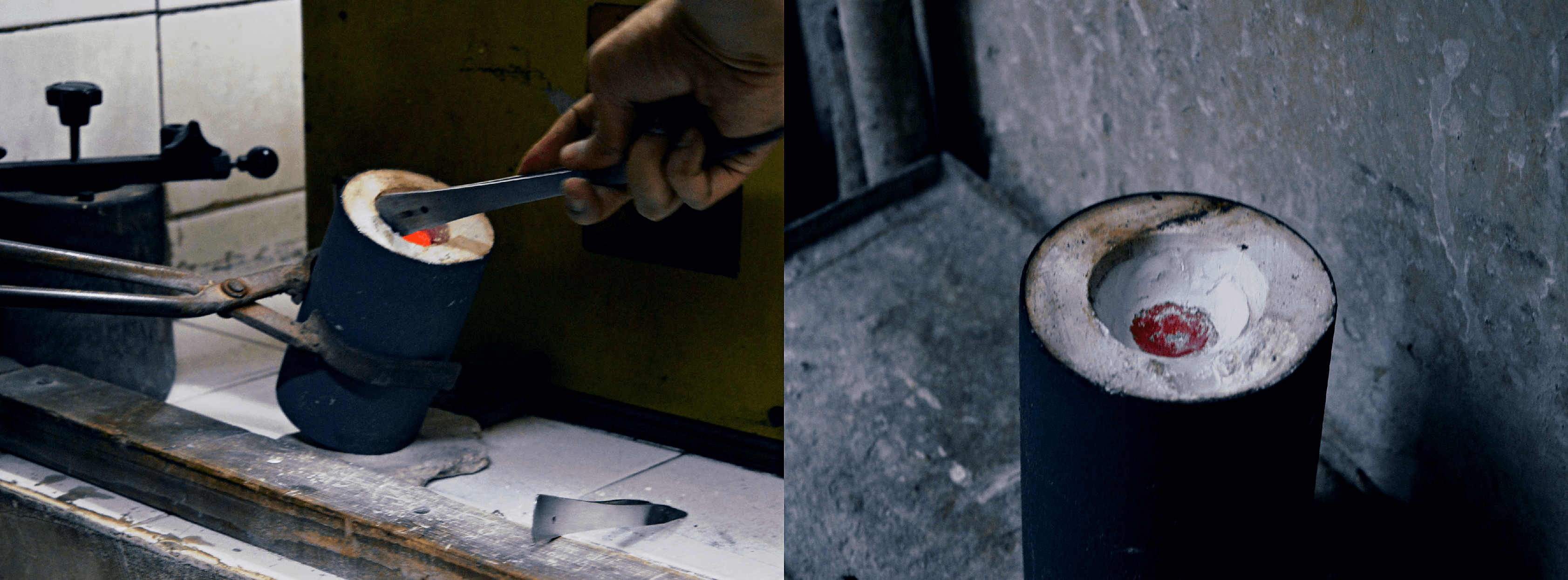

Read more +11 April 2016 By mmgoldcaster in UncategorizedCASTING

The desired steel alloy is melted and subsequently brought to casting temperatures. After the tree has been sintered, the tree is removed from the oven by a robotic arm and poured with metal. Once the trees have been poured, they are placed on a cooling conveyor where they are cooled with nitrogen. Our metals are

Read more +11 April 2016 By mmgoldcaster in Uncategorized

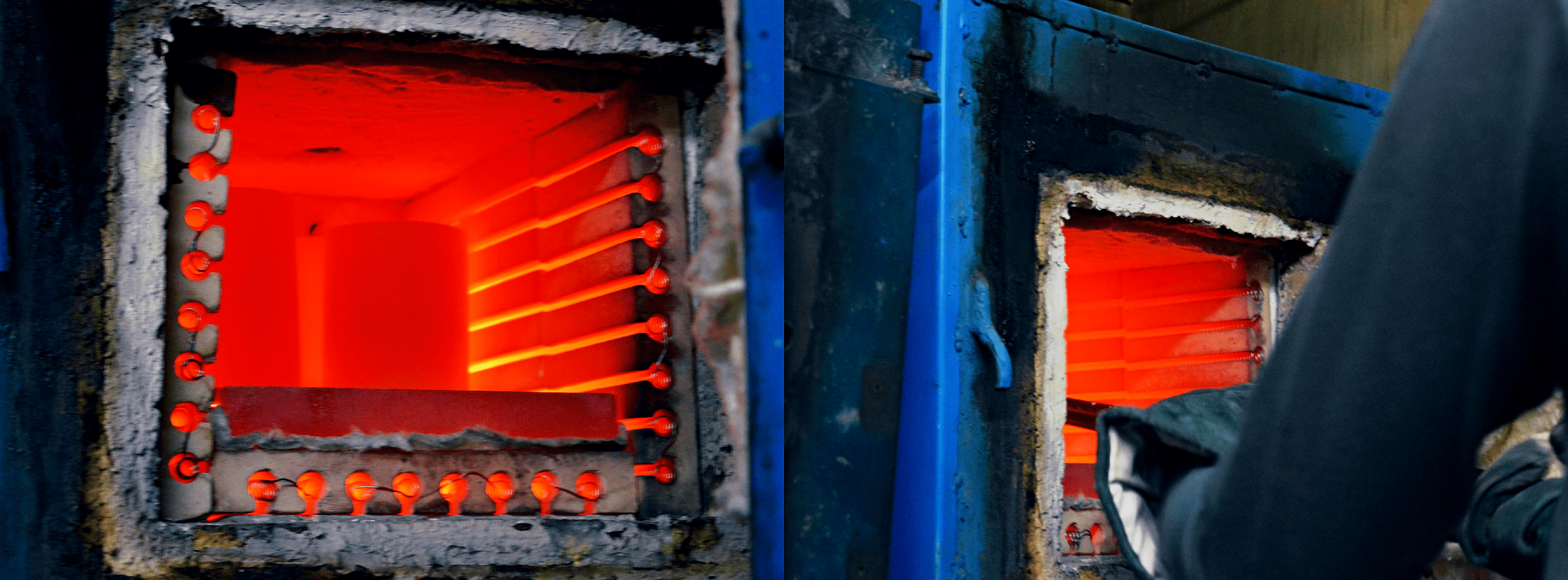

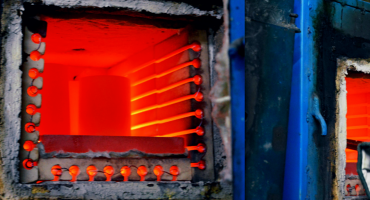

Read more +11 April 2016 By mmgoldcaster in UncategorizedKILN

The ceramic tree is then baked (stoked) at high temperatures and reaches its final strength through the sintering process. Any wax remains are burned out during this process. Before burning the investment is allowed to completely dry, which can take 16 to 48 hours. Drying can be enhanced by applying a vacuum or minimizing the

Read more +11 April 2016 By mmgoldcaster in Uncategorized

Read more +11 April 2016 By mmgoldcaster in UncategorizedPOURING THE INVESTMENT

The ceramic mould, known as the investment, is produced by three repeating steps: coating, stuccoing, and hardening. The first step involves dipping the cluster into a slurry of fine refractory material and then letting any excess drain off, so a uniform surface is produced. The process is to place the cluster upside-down in a flask

Read more +11 April 2016 By mmgoldcaster in Uncategorized

Read more +11 April 2016 By mmgoldcaster in UncategorizedWAX DESIGN

Wax Model, or sometimes called Cast or Pattern, is a replica of the final product generally produced using a preliminary material. Jewelry elements are best made with wax which has the flexibility to be built-up into almost any form you can imagine.